Order Fulfillment & Supply Chain Management

use case

Order Fulfillment & Supply Chain Management

Industrial Manufacturing - Energy Sector

Westinghouse Electric Company — global provider of nuclear energy technology and critical replacement parts for reactors worldwide.

Westinghouse used Fisent’s GenAI automation to rapidly validate complex nuclear parts orders, cutting review times and improving data accuracy.

Challenge

Westinghouse’s parts business manages thousands of highly specialized orders supporting nuclear plant maintenance cycles.

Westinghouse’s parts business manages thousands of highly specialized orders supporting nuclear plant maintenance cycles.

Each request for quote (RFQ) or purchase order (PO) involves complex technical specifications, QA requirements, and regulatory compliance checks. Manual review and validation across procurement, engineering, Quality Assurance, and fulfillment created:

- Long processing times (hours to days per document)

- Risk of data entry errors or missed spec mismatches

- Workflow bottlenecks delaying manufacturing and logistics

- Limited visibility and traceability across systems

The goal: streamline order intake, validation, and fulfillment orchestration without compromising quality or compliance.

Fisent BizAI Solution

Fisent BizAI GenAI Process Automation was deployed to automate end-to-end order validation and process routing across Westinghouse’s BPM (Pega) and ERP systems.

Key Capabilities:

- Document Ingestion & Parsing

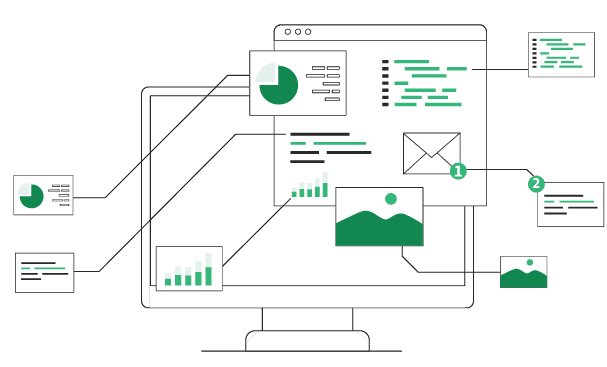

- AI-Driven Validation

- Exception Management

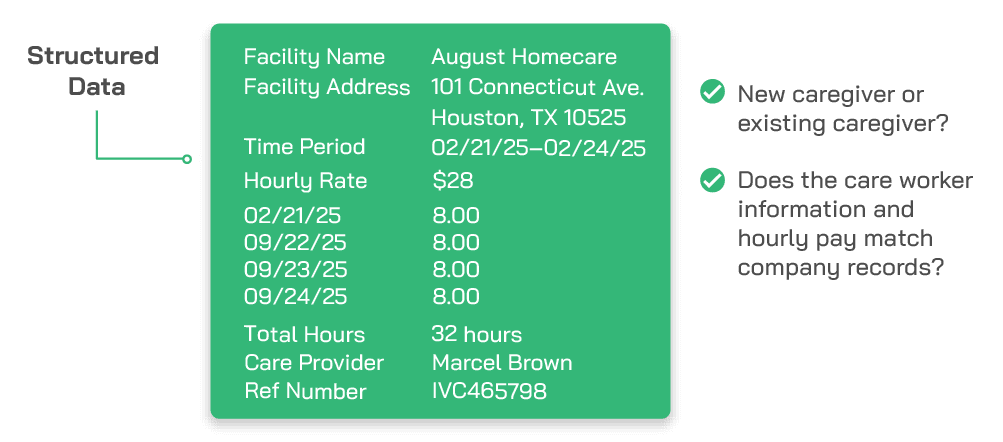

- Workflow Orchestration

- Feedback Loop

Extracts structured data from unstructured RFQs, Offers, and POs (e.g., part IDs, materials, specs, test procedures, etc.).

BizAI and enterprise workflow tools cross-check extracted data against master catalogs, QA standards, and regulatory tables.

Low-confidence or mismatched data is routed to engineers for review with a full audit trail.

Auto-triggers QA, procurement, and logistics workflows once validation completes.

Human corrections are applied to improve use case efficacy over time.

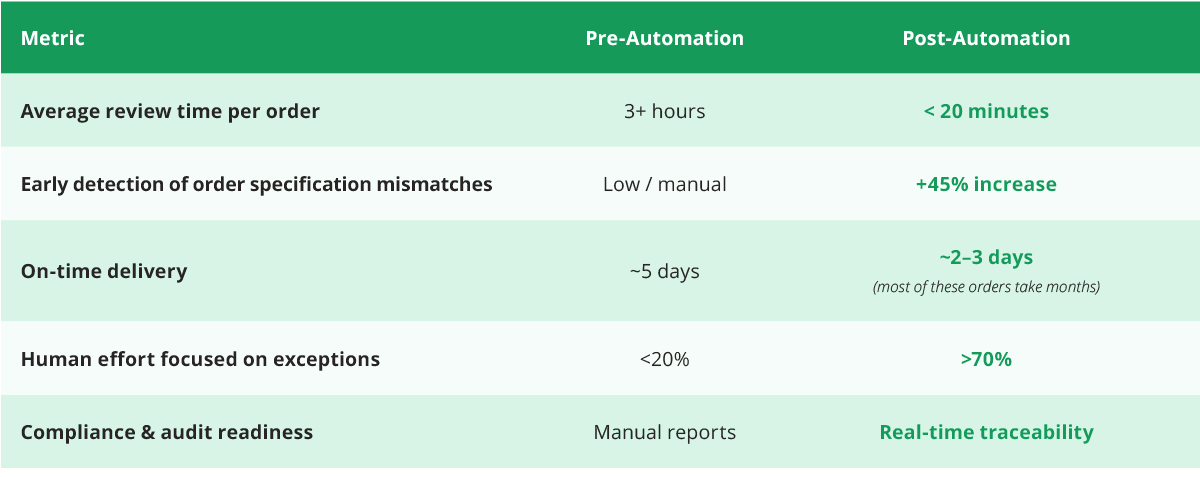

Business Outcomes

Key Takeaways

GenAI models can interpret highly technical, regulated documentation with high accuracy.

Automated processing of complex nuclear part Purchase Orders enables on-time delivery

Digitizing the RFQ/Offer Letter/PO process enables full transparency - allowing for continuous process improvements

Tight BPM/ERP integration ensures true end-to-end process automation.